Elastic but not too much...

Bioinks for extrusion-based printing need flow during the extrusion phase and should have shape-retention after the deposition of the filament. This behavior can be evaluated by two rheological parameters: the storage (or elastic) modulus G′ and the loss (or viscous) modulus G″ (Schwab et al., 2020).

The storage modulus, G′, relates to the amount of elastic energy stored during deformation. The loss modulus, G′′, measures the amount of energy dissipated by the material. G’ and G” are associated, respectively, with elastic shape-retention and viscous flow (Schwab et al., 2020).

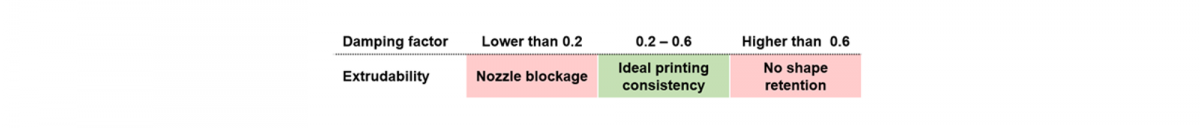

The G″/G′ ratio is known as damping factor, loss tangent or tan(δ). The damping factor gives valuable information on the balance between the viscous and elastic deformation properties.

Our ClaroBGI800 a gelatin-based bio-ink modified with methacryloyl groups. It is crosslinkable under UV light in the presence of a photo initiator (e.g. Irgacure 2959 or LAP). After equilibration at ambient conditions, ClaroBGI800 develops an excellent balance between structural integrity and extrusion uniformity with damping factor ranging from 0.2 to 0.6. These values have being correlated with high extrudability aligned with high cell viability in gelatin contained formulations (Gao et al., 2018).

References

Gao, T., Gillispie, G. J., Copus, J. S., Pr, A. K., Seol, Y.-J., Atala, A., Yoo, J. J., & Lee, S. J. (2018). Optimization of gelatin-alginate composite bioink printability using rheological parameters: a systematic approach. Biofabrication, 10(3), 34106. https://doi.org/10.1088/1758-5090/aacdc7

Schwab, A., Levato, R., D’Este, M., Piluso, S., Eglin, D., & Malda, J. (2020). Printability and Shape Fidelity of Bioinks in 3D Bioprinting. Chemical Reviews, 120(19), 11028–11055. https://doi.org/10.1021/acs.chemrev.0c00084

Want to empower the flow of your research? Connect with us via flow@claro.science