Benefits of gelatin in pharmaceutical applications

Gelatin is among the most widely used ingredients in pharmaceutical and medical applications, and with good reason: gelatin is almost universally tolerated, it displays very useful elasticity and clarity features, it melts at body temperature, and it is thermoreversible. Gelatin is a highly versatile ingredient with many benefits for pharmaceutical applications such as capsules, tablets, and more.

Hard and soft capsules

Gelatin is widely used to create the shell for both hard and soft capsules, providing an effective means of protecting the contents from light, atmospheric oxygen, contamination and microbial growth as well as masking taste and odor.

Hard capsules represent 75% of the gelatin capsule market. 1Also known as two-piece capsules, they consist of two cylindrical shells with a cap that fits closely over the body to form a hermetically closed unit. They can be produced in sizes ranging from 000 to 5 for humans and may be transparent or colored. Imprinting is also possible.

Hard capsules are commonly filled with powders, granules, pellets and mini-tablets. They can also be filled with liquids and pastes utilizing methods that have been developed to seal and package the capsules while maintaining drug safety standards.2

Soft capsules, meanwhile, feature a one-piece, hermetically sealed flexible shell, benefiting from gelatin’s ability to dissolve in hot water and form a gel upon cooling. They can have either a liquid or semi-solid filling, with the ability to create shells with different shapes and colors.

While soft capsules make up only around one quarter of the gelatin capsule market, they offer significant advantages over many traditional oral dosage forms. These include the protection of APIs, improved swallowability, and the ability to readily dissolve in the gastric juices of the gastrointestinal tract. In addition, the absorption of poorly soluble compounds encapsulated in soft capsules may be higher compared to conventional dosage forms.3

One challenge for both hard and soft gelatin capsules is crosslinking, which can affect bioavailability. Crosslinking is a natural behavior by which gelatin molecules link together and dissolve more slowly due to circumstances such as humidity or storage temperature, or the chemical properties of a capsule’s filling. The best-known compounds that induce crosslinking reactions with gelatin protein chains are aldehydes, which typically form a crosslink with amino groups of gelatin.

Modern solutions can reduce crosslinking in soft capsules, improving bioavailability by providing better dissolution and stability over time.

Tablets

Gelatin can be used as a binder or coating for tablets, which offers a lower-cost alternative to capsules. Tablets also provide the possibility of notching for dose splitting and there is no risk of crosslinking.

However, tablets are limited to solid APIs and excipients, while dissolution is slower, formulation is more difficult, and there is less protection of active ingredients against oxygen and light. Swallowability is also more challenging.

As a binder, gelatin can glue together powders during granulation such as starch, cellulose derivatives, and gum acacia. Gelatin coatings can also help overcome some of the tablets weaknesses. These include providing improved swallowability, reducing taste and odor, and helping to protect APIs against oxygen and light.

Microencapsulation

The microencapsulation process involves coating particles or droplets with a gelatin shell to create tiny capsules. Its uses include lipophilic vitamins as well as flavors, colors, pesticides, herbicides and carbonless copy paper.

Microencapsulation can provide multiple benefits, including protecting the particles from degradation caused by oxygen or light, masking their taste and odor, controlling their release rate, and improving their handling qualities.

Medical devices

Gelatin has various benefits that make it ideally suited to a range of healthcare applications. It is almost universally tolerated, with excellent cell compatibility and minimal immunogenicity. It is also highly purified, with no risk of contamination, and it offers highly reproducible production in addition to well-controllable physical parameters.4

Its uses include hemostatic sponges, which not only stanch blood effectively but are bioresorbable and accelerate the healing process by facilitating the migration of new tissue cells. Ostomy patches, meanwhile, use gelatin as an adhesive to the skin.

Gelatin bone plugs provide stability after joint surgery and, because of their biodegradability, they do not need to be removed afterward. Gelatin also has a long history of use as a plasma expander, offering a relatively cost-effective means of increasing plasma volume.5

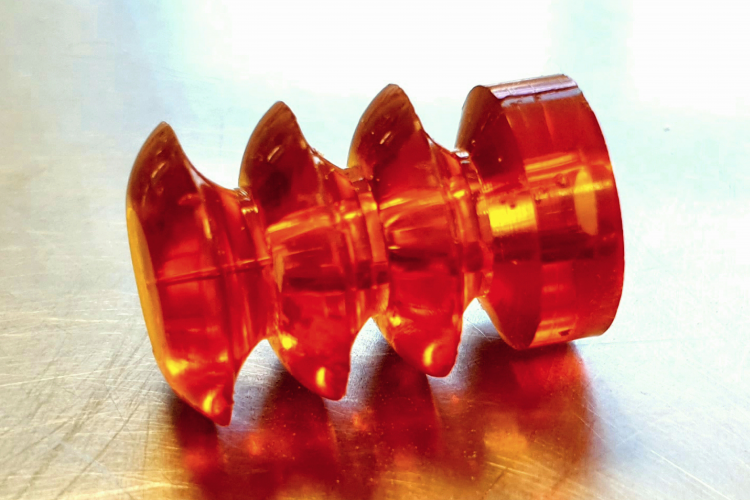

Most recently, gelatin has been used in 3D printing to fabricate single-layered structures and multi-layered complex 3D structures for tissue engineering.

Its wide-ranging uses ensure gelatin is considered to be an innovative excipient with decisive advantages.

[1] Strategic Analysis Inc. (2018)

[2] Schrieber, R. & Gareis, H. (2007)

[3] Gullapalli, R.P. ‘Soft gelatin capsules (softgels)’ Journal of Pharmaceutical Sciences (2010)

[4] Schrieber, R. & Gareis, H. (2007)

[5] Saw, M.M. et al. 'Benefits and risks of using gelatin solution as a plasma expander for perioperative and critically ill patients: a meta-analysis' Anaesthesia and Intensive Care (2012)